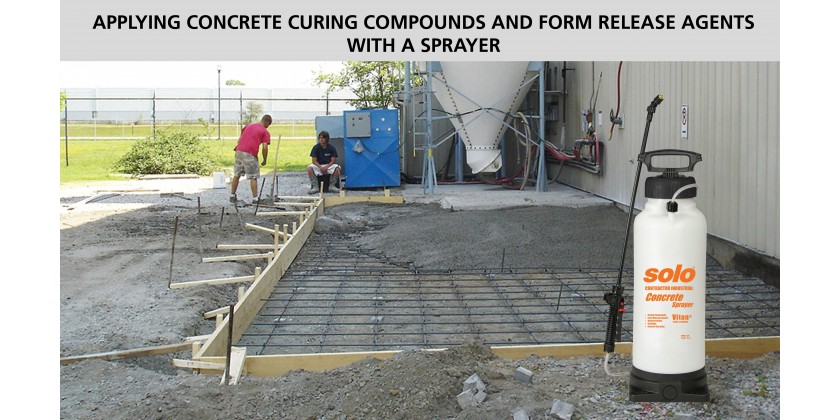

Heavy-duty tools come to mind when most people think of the construction: saws, drills, brick, and chainsaws. Not many think of sprayers, but sprayers are critical tools for concrete curing and forming agents.

Concrete Curing

Concrete curing is a process done after concrete is poured. It is the process of maintaining moisture in concrete at the right temperature and humidity. This process can take up to 28 days and prevents concrete from drying, shrinking, and cracking[1].

There are several methods of concrete curing. Each method depends on various factors including the curing material, size, shape, and age of the concrete as well as the desired result of the concrete. Sprayers can be used throughout the curing process but are most notably used for:

1) Spraying to keep concrete moist and humid

2) Applying a concrete curing compound to create a barrier for retaining moisture.

Form Release Agents

Form release agents are used to prevent concrete from sticking to the framework supporting the concrete. This makes removal of the framework easier by creating a barrier during the curing process.

There are two types of form release chemicals: physical and reactive[2]. Physical agents create a physical barrier using petroleum or oil, while reactive agents use fatty acids or other ingredients designed to react with lime in concrete.

Form release agents should be applied to a clean frame before any reinforcements have been installed. When it comes to applying form release agents, less is more[2]. This is why sprayers are effective tools for applying form release agents. Pump sprayers have adjustable nozzles that can achieve a fine mist setting for applying a thin, even layer of chemicals onto a surface.

● All Viton® seals for durability and safety with a wide variety of chemicals.

● Large base for added stability which can accommodate the wheel set and handle (accessory kit, part # 49211).

● High-density polyethylene (HDPE) tank with ultra-violet inhibitors; will not dent, crack, or corrode.

● 48” nylon-reinforced hose for extended reach.

● Built-in air inflation valve allows pressurizing the sprayer using a compressor or air source.

● Large pump pressurizes the sprayer as much as 50% faster than the competition.

● Automatic pressure relief valve releases pressure at 45 psi and may be used to release pressure when desired.

● 28” unbreakable wand and commercial shut-off valve assembly.

● Fitted with a 1 gpm, 110º flat fan nozzle for spraying higher solid content curing compounds.

● Includes jet stream, flat fan, hollow cone and plastic adjustable nozzles for general spraying tasks. Accepts TeeJet ® type nozzles.

● 4.5” opening allows easy filling and thorough cleaning.

● Extra large pump handle with built-in wand retainer for convenient carrying and pumping.

● Commercial shut-off valve with lock-on/lock-off feature reduces user fatigue.

[1] https://www.concretenetwork.com/curing-concrete/

[2] https://precast.org/wp-content/uploads/2015/03/TechNote-Proper-Application-Form-Release.pdf